SiccaDania Filtration’s portfolio of RO plants is also based on our customized standard solution approach, maintaining high-level quality at attractive CAPEX/OPEX. The plants are branded as RO40™, RO60™, and RO100™ and alone or combined target the best solution to meet concentration levels and overall performance with optimal CAPEX/OPEX parameters.

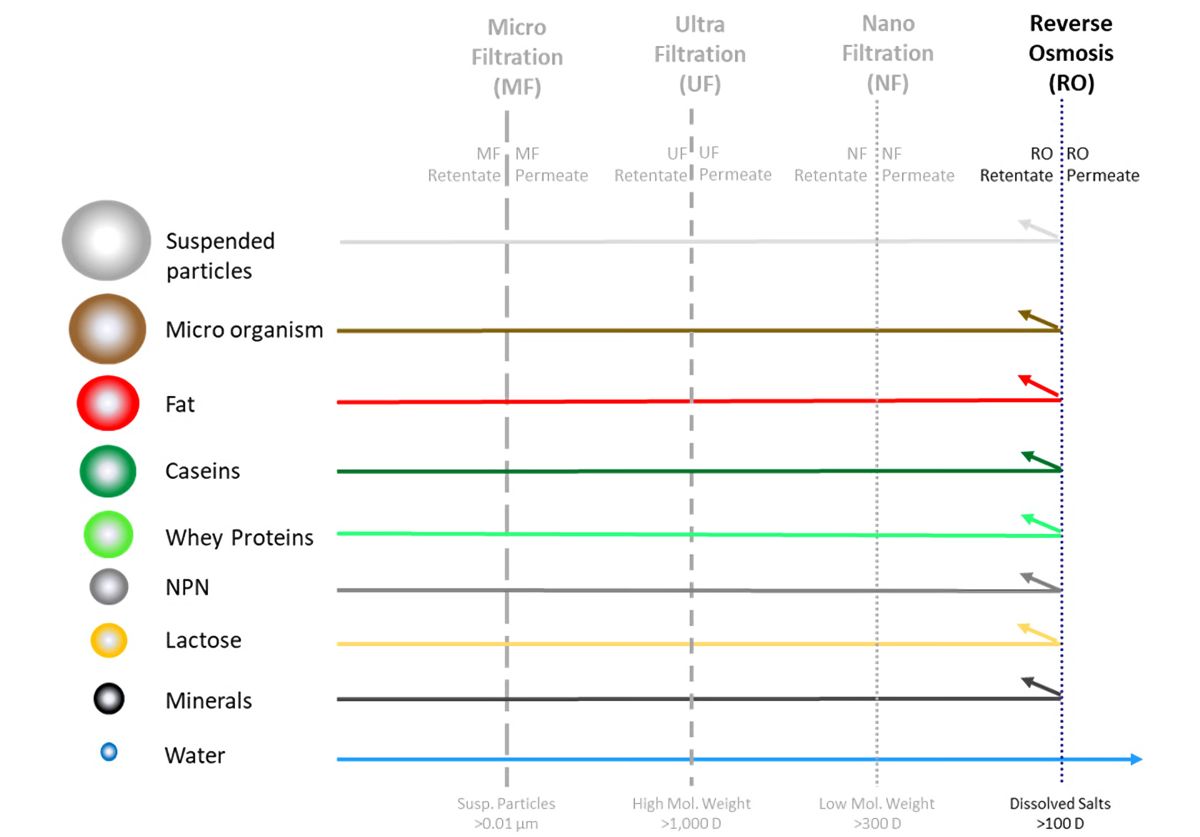

Reverse Osmosis applications involve pure concentration and volume reduction processes. The RO membrane rejects more or less all solids, and only water passes through the membrane. RO technology is extremely efficient for a high concentration of milk, whey, and permeates.

RO technology is also used for “polishing” of condensate and permeate, which allows the final output of processed “water” to be reused for several applications.

Combining technology for optimal results

Any RO/NF/Evaporator process will produce a permeate/condensate stream that can be polished for re-use in production/CIP again. The process is in short called ROP (P for polishing) and widely applied across productions, where water savings are critical to the overall business and bottom line.

Dairy

- Raw milk concentrate

- Skim milk concentrate

- Whole milk concentrate

- Milk solid concentrate

- Whey concentrate

- Permeate concentrate

- Polished water (ROP)

- Recovery of sugar

- Concentration of sweeteners

- Recovery of water

- Condensate and permeate polishing

- Vegetable protein concentration & purification

- Resin regeneration

- Effluent concentration and the recovery of sugar and water

Reverse Osmosis Tecnical Data